Downstream Processing

Raw natural gas undergoes multi-stage processing before it is a marketable natural gas fuel.

Processing

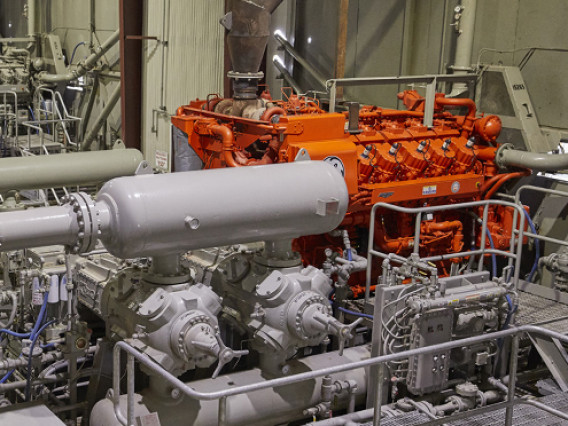

Today natural gas accounts for 23% of the world’s energy consumption and demand is growing. However, raw natural gas as it comes from the ground must be processed -- to clean it and remove impurities, including water, to meet the specifications for marketable natural gas – and to separate out valuable components including natural gas liquids such as ethane, butane and propane. Compressors driven by INNIO's Waukesha* gas engines are used throughout gas processing facilities.

How it works?

Raw natural gas undergoes multi-stage processing before it is a marketable natural gas fuel. Variable-speed Waukesha natural gas engines drive compressors that pressurize and circulate gas through various stages of processing, enhance conditions for chemical reactions, and recover and recompress processed gas.

Bringing natural gas from well head to market requires dependable engine-driven compression systems that operate efficiently to keep the gas flowing and productivity and profitability high.

INNIO's Waukesha gas engines for compression applications offers multiple options to address individual operational needs and widely varying local emissions requirements.

Features & Benefits

- Durable: INNIO's Waukesha gas engines are designed and built to perform within punishing environments.

- Variable speed capability: Gas engines’ wide turndown range handles partial-load operation more efficiently than electric motor-driven compressors.

- Reduced energy waste: Captured waste engine (exhaust) heat is used for other processes, lowering energy and operating costs, and reducing carbon emissions.

- Emissions flexibility: INNIO offers technology options to meet most local air quality mandates.

- Lower emissions per horsepower: Rich-burn Waukesha gas engines with 3-way-catalyst enable more horsepower per site for more productivity and profit.

- Total engine control: INNIO’s Waukesha ESM* fully integrated control and diagnostics system optimizes engine performance and maximizes uptime.