For more than 20 years, Q8Oils and INNIO Group have maintained a strong and enduring collaboration, marked by consistent innovation and achievement. Their latest co-engineering success is based on the development of the Jenbacher S Oil 40, which is used extremely successfully in the latest generation of the Jenbacher 3 series – the J312 F engine. As a result, Bioenergie Aspach has been able to increase the efficiency and profitability of its energy production.

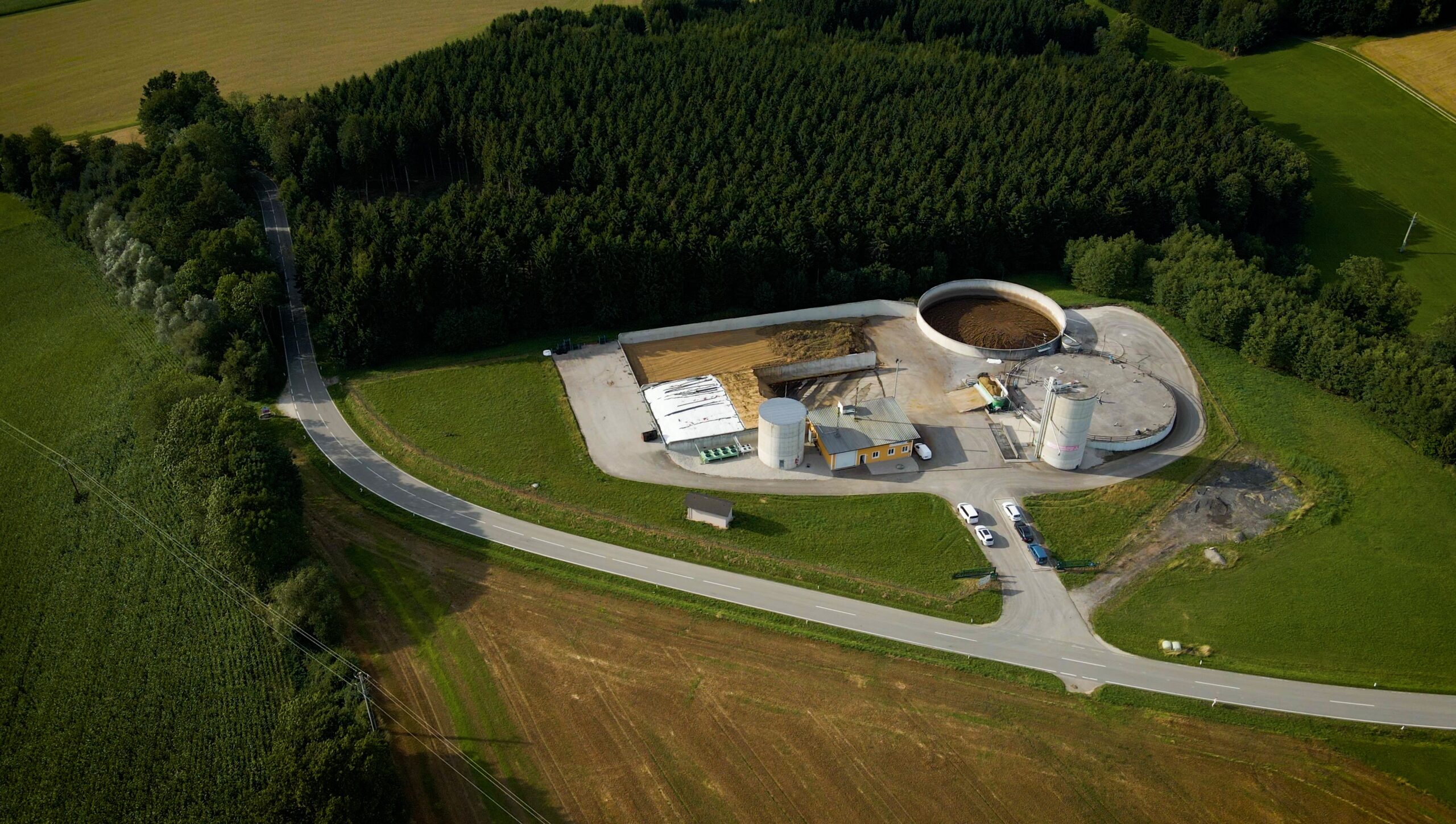

In 2005, INNIO Group began a journey with Bioenergie Aspach under the guidance of Johann Angleitner-Kettl, managing director of Bioenergie Aspach, and his colleagues Bernhard Seidl and Franz Schachinger. The exceptional alliance continued in 2020 with the addition of the next F-generation Jenbacher J312 F engine. In fact, Bioenergie Aspach was one of INNIO Group’s first customers worldwide to install the Jenbacher J312 F engine – an innovation that has marked a new era of efficiency and reliability in power generation. The customer attests to the remarkable results achieved with the Jenbacher J312 F engine. The company has been able to increase electrical efficiency and reduce operating costs simultaneously. All of these improvements are being made at the same time as the usual reliable provision of the electrical and thermal energy required for the heating plant.

The trust between Bioenergie Aspach and INNIO Group led to the signing of a new service contract for the engine’s next 60,000 operating hours in 2023, supporting the continued reliable operation of the Jenbacher J312 F engine.

20

collaboration

20,000 oh

same oil

>3

with no oil drain

Innovation sparked by collaboration

One reason for Bioenergie Aspach’s success story: From the very beginning, the engine has been lubricated by Jenbacher S Oil 40. This innovative lubricant was designed specifically to meet the demands of Jenbacher engines running on non-natural gas (including, but not limited to biogas, sewage gas and landfill gas). It combines the benefits of very long oil drain intervals and the resulting reduced engine downtime with improved engine cleanliness.

The exceptional combination of INNIO Group’s engineering expertise and our innovative products has made Jenbacher S Oil 40 a global success.

Nina Tiedemann, Business Development Manager Energy at Q8Oils

Q8Oils and INNIO Group recommend Jenbacher S Oil 40 for all engines running on non-natural gas (including, but not limited to biogas, sewage gas and landfill gas). For engines that have been in operation previously, two to three oil changes are required to achieve the full benefit of Jenbacher S Oil 40, because of its cleaning properties. The carefully balanced Q8Oils additive-technology consists of specially selected detergents and dispersants that help remove potentially accumulated deposits from the engine while enabling Jenbacher S Oil 40’s full potential.

Proven performance

The Jenbacher J312 F engine at Bioenergie Aspach continuously operated for more than three years and more than 20,000 operating hours without requiring any oil drain.1 Although this result has been achieved by a single customer and the individual results may vary, this accomplishment clearly demonstrates the savings potential that Jenbacher S Oil 40 can offer. Continuous oil analysis during this period has revealed good oil quality that remains at a safe distance from the condemning limits. The results were confirmed through detailed Total Base Number (TBN) and Total Acid Number (TAN) values, as well as the oxidation data. At the biogas plant in Aspach, an endoscopic inspection revealed an overall good condition of the important engine components.

Not only was the customer able to operate the engine for 20,000 hours without the need for an oil drain, but, in addition, frequently conducted lab analyses have continuously revealed a good oil condition.

Rene Eberharter, Service Sales Manager for INNIO Group’s Jenbacher brand

Collaboration is key to success

The collaboration between Q8Oils and INNIO Group has not only brought a great synergy but also has demonstrated how innovation can drive the power generation industry forward. The success of Bioenergie Aspach is an example of what can be achieved when two key industry players collaborate to push the boundaries of what is possible. For more information on Jenbacher S Oil 40, visit this link. If you have any questions or inquiries, please contact JenbacherSOil40@Q8Oils.com.