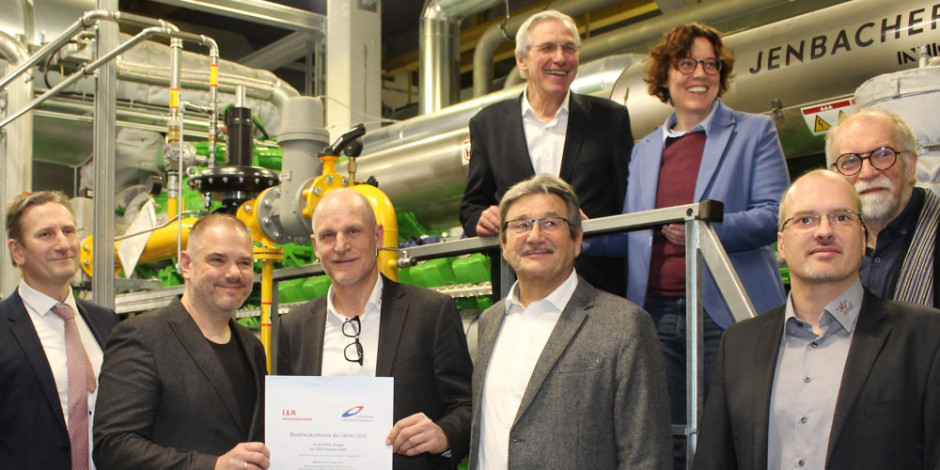

To be named CHP of the Year by the Energie & Management (E&M) magazine and Bundesverband Kraft-Wärme-Kopplung (German Combined Heat and Power Association), a project must be based on a pioneering concept, and it must be rated at the top by a panel of experts regarding solution concepts, partners involved, planning, technical implementation, and operation.

The new energy center in Stralsund, equipped with two highly efficient Jenbacher assemblies, succeeded in doing just that.

9 MW

Electrical Output

9.6 MW

Thermal Output

J624

2x

At least 60%

Heat Supply from CHP Plant

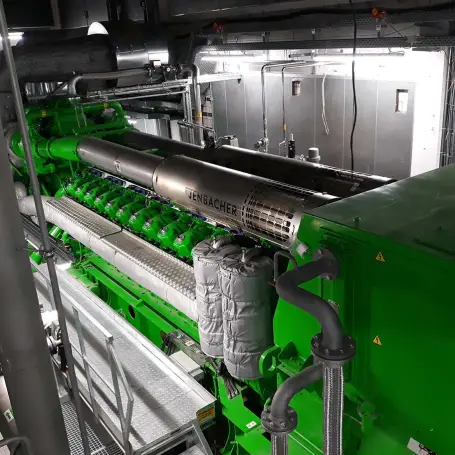

Through January 2022, Stadtwerke Stralsund was already generating more than 60% of its heat through highly efficient combined heat and power (CHP) plants, which supply heat as well as power. Three CHP plants with a total electrical output of 6.5 MW were in operation at the energy center on the Prohner Straße site. To equip itself with even more power for the future, plant operator SWS Energie decided to upgrade the CHP plants after the old CHP feed-in tariffs expired. They were replaced at the beginning of 2023 with two innovative Jenbacher J624 assemblies from the INNIO Group, each with an electrical output of 4.5 MW and a thermal output of 4.8 MW. In conjunction with two newly installed heat pumps, the Stralsund plant’s total thermal output increased from 6.5 MW to 11.6 MW, and the total electrical output rose to 9.0 MW. Thanks to this increase in capacity, the plant’s full utilization period can be reduced to between 3,500 and 5,300 hours per year. In addition, the total heat production can be significantly increased to 61 million kWh with an annual power generation of 48 million kWh. In all, the Jenbacher CHP plants guarantee a much more economical plant operation.

More than just innovative

With our new energy center in Stralsund, we are providing a boost to the energy transition together with the INNIO Group. Our creative solutions go beyond the existing legal requirements for iKWKs, and we see our innovative CHP system as a consideration for legislator going forward.

Ralf Bernhardt, Managing Director SWS Energie

Present innovative CHP system subsidies require that heat pumps generally supply a regenerative heat share of at least 30% (river water, ambient air) separately from the CHP plant. To achieve this, the atmosphere first is heated unnecessarily with the available waste heat before a less efficient air/water heat pump provides the necessary regenerative share of thermal energy. However, the new energy center in Stralsund uses the waste heat from the CHP system directly via a water heat pump and thus presents a completely new, significantly more efficient and, therefore, more sustainable approach. In addition, the CHP plant switches off as soon as excess renewable energy is available, and the power-to-heat system takes over the provision of sustainable heat for the district heating network. In this way, Stadtwerke Stralsund’s new energy center is making another important contribution to the energy transition.