Low carbon & circular products

Design considerations of products

INNIO develops environmentally sound, safe, and reliable products and solutions for our customers. Starting from the selection of raw materials that are being used as an input for the production of our engines, INNIO’s dedicated Procurement team collaborates closely with suppliers, ensuring that the reused, remanufactured or reclaimed raw materials used are of top quality. The team uses a comprehensive and detailed methodology for the selection and calculation of the recycled materials, identifying and managing challenges and potential improvement areas and building robust paths to achieve our commitment. Our framework showed that the recycled, remanufacturable, reclaimed materials used as input for our energy solutions exceed 50% since 2019. We understand that this is already a great baseline but also that our commitment is ambitious. For this reason, we are dedicated to continuing combining the efforts with our stakeholders and actively drive meaningful progress toward our goal.

Furthermore, as regards the end-of-life treatment of our products, all our Jenbacher and Waukesha engines are manufactured to be 100% remanufacturable and reused, having multiple lifecycles. Through our Reman product stewardship (reUp) program, we provide lifecycle maintenance, reconditioning, and retrofitting services, supporting our customers’ operations throughout the life of our products. The reconditioning and modernization of engines and parts increases their reliable service life and improves the current operational performance of installations and enables customers to meet tightening future regulatory requirements. A remanufacturing process can typically be repeated twice giving the product a total of three lifecycles. Considering an average lifecycle is around 10 years, we can extend total usable time to 30 years.

The remanufacturing and end-of-life treatment of our solutions is governed by the VP Services and our dedicated team. The VP Services works closely with the Chief Technology Officer and the engineering team and reports every week to the Executive Board.

Product & service safety considerations

Since the beginning of our existence, we have been determined to always deliver safe, high-quality products. The proper and safe functioning of our products, including the health and safety of our customers, is achieved by following proper safety procedures, tests, and protocols for products. This helps us reduce the risk of product safety-related adverse impacts and strengthen our corporate brand. To earn and maintain the trust of our customers through the provision of top quality and safe equipment, INNIO has set the company-wide goal of zero product defects and recalls.

Regulatory requirements

INNIO has comprehensive systems in place to promote quality improvement globally, with top executives taking responsibility for ensuring these promotions are successful. These are regulated by the EU Machinery Directive, harmonized under norm EN 12100 (machinery safety risk assessment), with which INNIO—as original equipment manufacturer— complies. With respect to U.S. manufactured equipment, INNIO aligns with the National Fire Protection Association (NFPA), the Canadian Standards Association (CSA), the UL standards, and other guidelines.

Governance

INNIO’s overall product offerings, new product introductions (NPIs), research & development (R&D), and safety are governed by the Chief Technology Officer, who is also a member of the Executive Board. The Product Safety Board, which includes INNIO’s Vice Presidents of Quality, Product and Services, meets each week. This body governs all of product safety, from NPI to the Residual Risk Summary. Policies, instructions, operating procedures, safety instructions, and safe operation handbooks are managed as part of INNIO under a business process modeling tool. The end users of our products and services have digital access to the guidelines and instructions, and they sign conformity as part of each contract. Conformity for product and service safety is provided by external audits and the issuance of ISO 9001, which covers 100% of INNIO’s production facilities and products.

Life-cycle emissions assessment

We believe that the identification of the life-cycle impacts of our products is essential for understanding their total environmental impact, identifying environmental hotspots in products and materials, and driving action for innovation and future improvements. A life-cycle emissions assessment (LCA) is a cradle-to-grave analysis. This technique assesses the environmental impacts associated with all the stages of a product’s life, from raw material extraction through materials processing, manufacture, distribution, use, and remanufacturing. The methodology of life cycle assessment we use is in line with the World Resource Institute Greenhouse Gas Protocol, the ISO 14064, and PAS 2060 corporate standards. The reference engines for the study are JB 320 and WK VHP 12. These engines provide the most comprehensive data accessible. For the study we use actual data, including data provided by suppliers or other value chain partners. In some cases, model-based assumptions are made. In general, assumptions are made in a conservative way, to not underestimate the impact from uncertain data.

For the LCA calculation we included carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) emissions, which are regulated under the Kyoto Protocol. As regards the management of the life-cycle emissions of our products, we take careful consideration of the design and manufacturing methods, and we continue to innovate our energy solutions that keep INNIO and our customers growing. The cautious selection of our suppliers and the quality and recyclability of the materials we use, as well as the optimization of upstream and downstream transportation are critical for INNIO’s LCA management. Finally, the maintenance, remanufacture, and reconditioning of products and components offered by INNIO’s comprehensive Reman (reUp) program increases their reliable operational and service life, and with the latest technology upgrades, we modernize and improve them.

A continuous improvement culture

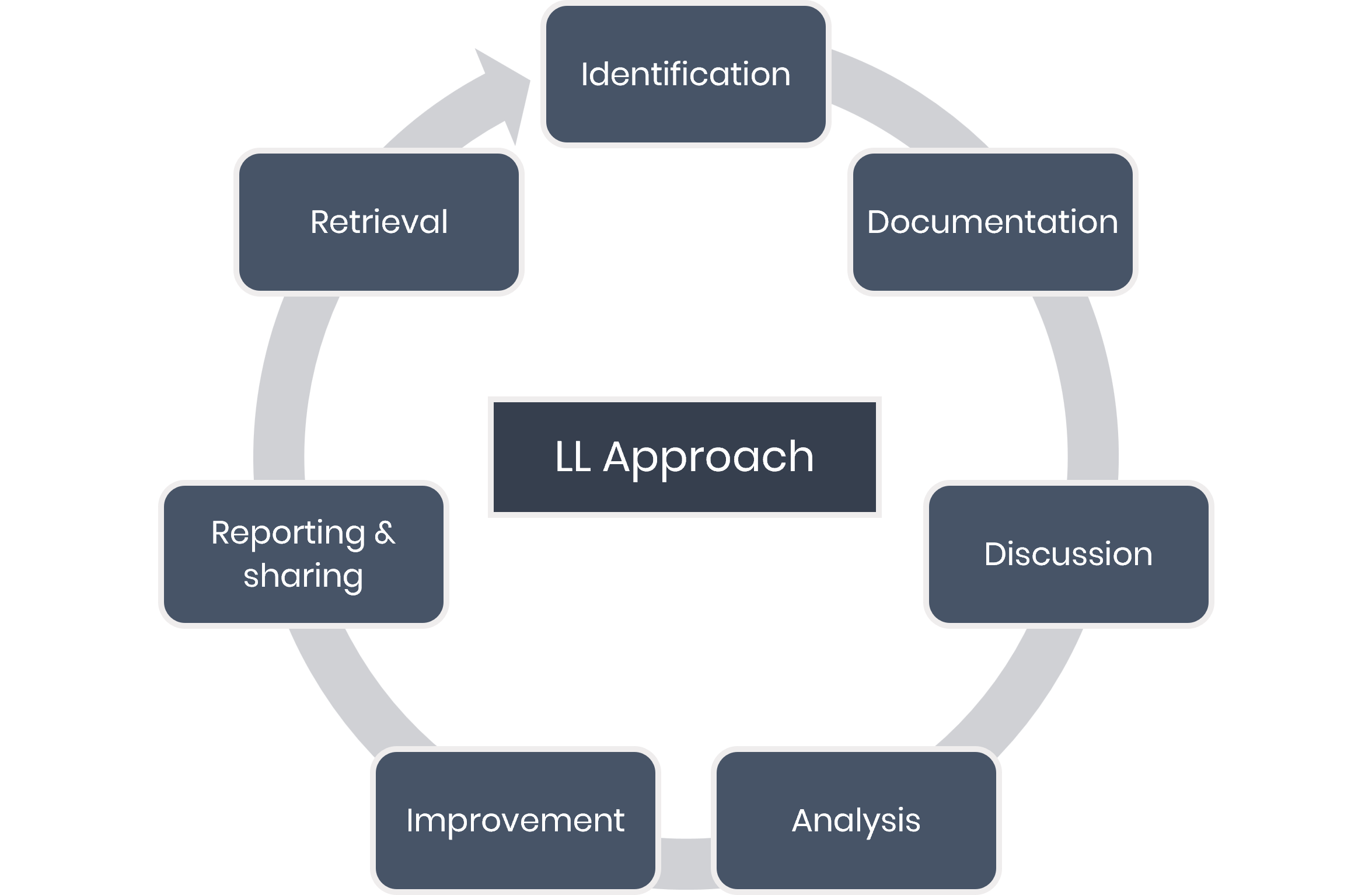

It is extremely important for us to offer products and services of top quality and top environmental performance. At the same time, we always make sure to continue improving our production practices, as well as the quality, efficiency and environmental performance of our products throughout their life-cycle. This is achieved by our systematic Lessons Learned (LL) approach guided by our strategy and environmental targets, as well as our Quality, Environment, Health and Safety, and Zero Defect Policy. The LL approach is a step-by-step process, though which we continuously learn, improve, and get closer to our goals and target.

The steps include:

Our continuous improvement culture is managed in compliance with legal requirement and coordinated by the collaboration of multiple teams across the company, including the Quality-, Engineering & Design-, EHS-, Procurement- and Product Management department. The depth and breadth of our operations and products advances are reflected in our certifications by the International Organization for Standardization (ISO) that include ISO 45001 (Occupational Health & Safety), ISO 14001 (Environmental Management), ISO 9001 (Quality management), ISO 50001 (Energy management), and ISO 55001 (Asset Management System).

/ Contact

Contact an Expert

Send us a message and we’ll contact you to start a conversation.