Additional Major Order from VoltaGrid

1.5 GW for Behind-the-Meter power generation

Largest Order in Company History

Delivering Power Generation for One of the World’s Largest Data Centers

INNIO Powers UK Grid Stability

/ See our company video:

/ Industry potential

Business fields and growth opportunity

INNIO Group is well positioned to be at the center of the energy transition.

> 100 GW

The global surge in AI and cloud is fueling explosive growth in data centers – with > 100 GW of new capacity expected by 2030.

(IEA Energy and AI, April 2025)

~ 2,000 TWh

Increasing industry electrification and EV penetration drive up electricity consumption by ~ 2,000 TWh (+ 11%) by 2030, excluding data center demand and China growth.

(Bloomberg New Energy Outlook 2025)

~ 350 Bcm

Global LNG supply capacity is expected to increase by ~ 350 billions of cubic meters (bcm) by 2030, up more than 50% from 2024 levels, driven primarily by an increase in liquefaction capacity from North America and Qatar.

(J.P. Morgan 2025)

/ Our Project Highlights

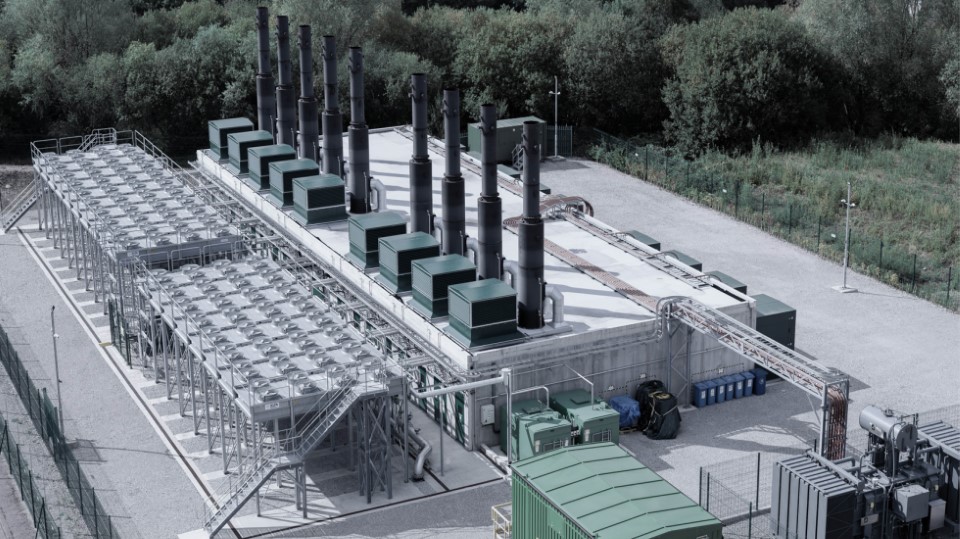

Peaking Power Plant Enhancing National Grid Security

As electricity demand continues to grow, so does the challenge of energy security—creating the need for flexible capacity that can maintain grid stability and respond to peak demand. In Great Britain, a peaking plant equipped with fast-start, flexible engine technology from INNIO is meeting sudden surges in demand and compensating when renewable generation is low, adding security and stability to the grid.

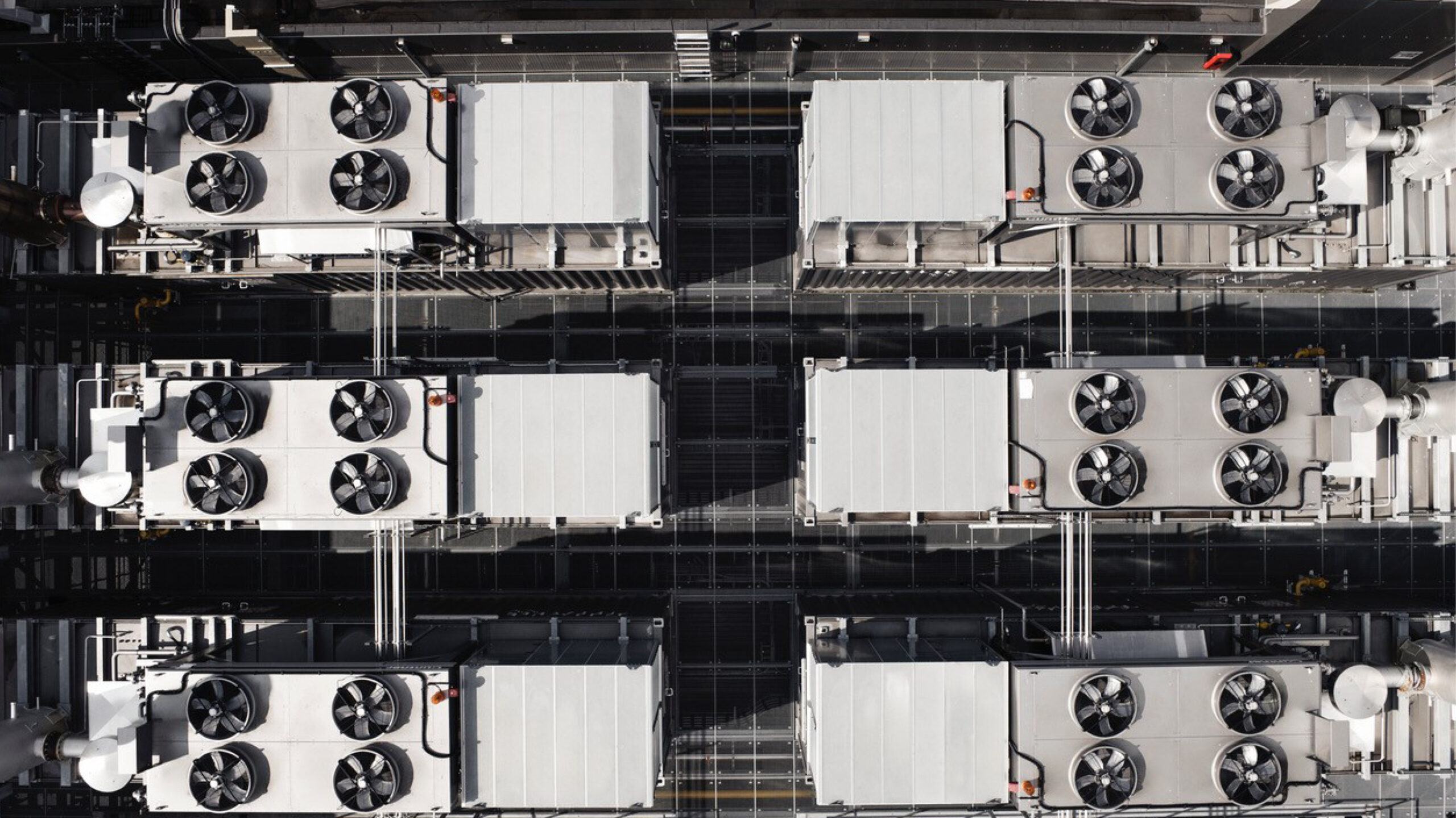

Dependable Energy Supply for Critical Data Center Operations

INNIO addresses one of the greatest challenges faced by data centers worldwide: ensuring a stable and secure energy supply. At NorthC Datacenters in the Netherlands, our containerized solution provides reliable backup power for critical operations. With rapid installation and dual-gas capability, we help lower the carbon footprint while delivering reliable energy.

Replacing Coal Fired Power with CHP in Germany

The new modern and flexible combined heat and power plant replaces the coal-fired power plant on the Kieler Förde with Jenbacher technology from INNIO. Thanks to its high efficiency and the environmental benefits of gas, the new facility is reducing its carbon dioxide emissions by 70%, equivalent to an annual saving of almost 1 million metric tons of CO2 or removing 500,000 cars from the road. Going forward, INNIO is working with Stadtwerke Kiel to make the coastal power plant climate-neutral by using green gases with a higher hydrogen content.

Resilient Power for NYC’s Iconic Development

The largest private real-estate development in US history, the project transformed the West Side of Manhattan by developing 17 million square feet of commercial and residential space. Hudson Yards is innovating by incorporating a 13.2 MW Jenbacher CHP system to decrease energy costs and improve resiliency across the site.

Lower Emissions in Canada

Although new technologies in fuels and energy sources are being developed, the current installed base of natural gas generators needs to reduce CO2e emissions now. That’s why INNIO supported Ember Resources in navigating various emission reduction programs while upgrading our Waukesha engines that are in operation to reduce their CO2e footprint.

Microgrids for Safe, Robust, Efficient Power at Airport

Microgrids are decentralized power solutions that produce energy and supply it to the local consumers. Watch this film to see how an airport in Pennsylvania uses Jenbacher´s innovative technology in a first-of-its-kind solution ensuring greater power reliability, enhancing public safety and creating cost efficiencies.

/ Our People

Our People

Our team is guided by a deep commitment to diversity. We strive to build a workplace environment that encourages innovation and allows all individuals to flourish. Active development, employee engagement, and diverse employee benefits are essential elements of the INNIO culture.

Brittany B.

Sandra R.

Karan M.

Melissa S.

Osagie B.

Mustafa I.

Timara B.

Sarah P.

/ Contact

Contact an Expert

Send us a message and we’ll contact you to start a conversation.