As an instantly dispatchable, affordable energy source, conventional gas will be the bridge to a clean energy future. As companies shape their Environmental, Social, and Governance (ESG) strategies, there is a strong focus to maximize the impact of their investments using cleaner sources of energy.

Waukesha engines have been operating in critical applications for over a century, providing reliable power backed by innovation. As demands for low emissions and high performance increased, INNIO Waukesha developed a suite of upgrades and remanufactured products built on the VHP Series Five engine platform to reduce CO2e up to 50 percent while also lowering the total cost of ownership.

What is CO2e?

CO2e = CO2 + 25*CH4

Since INNIO Waukesha engines are utilized for gas lift, gathering, processing, transmission, and storage—nearly every process in the value chain of responsibly producing conventional gas—there is ample opportunity to provide customers with some of the best low carbon options available for compression applications. INNIO Waukesha has also recently leveraged its expertise in pursuing and advocating government-funded programs that reduce emissions and help reduce the upfront costs for Waukesha midstream operators. With the combination of low emission product offerings supported by government-funded emission reduction programs, INNIO Waukesha is well-positioned to help customers make dollars and sense with the Environmental or “E” portion of their ESG strategy.

Reuse, recycle – reUp!

There is an increased focus on fleet optimization and maximizing the value of every dollar spent in today’s oil and gas environment. The exploration and production (E&P) sector is continually evaluating the performance of its existing compression fleet, seeking out cost efficiencies to improve the bottom line. And, as shale basins in the US mature, some of the high-speed reciprocating installed based is being evaluated for upgrades or replacement in adherence with rapidly evolving emission policies and regulations. Upgrading a Waukesha engine or other OEM lean burn compressor package to a Waukesha Series Five rich burn compressor package offers better performance, lower fuel costs, and improves the existing CH4 inherent advantage of rich burn combustion, reducing CO2e by up to 50 percent.

Existing INNIO Waukesha and other OEM engines can be revitalized using various:

INNIO Waukesha reUp

remanufacturing programs

– exchange engine programs, short or long blocks,

or parts only—extending the life and value of the engine asset.

And these programs offer today’s most advanced specifications

backed by a same-as-new warranty.

Series Five Success Story

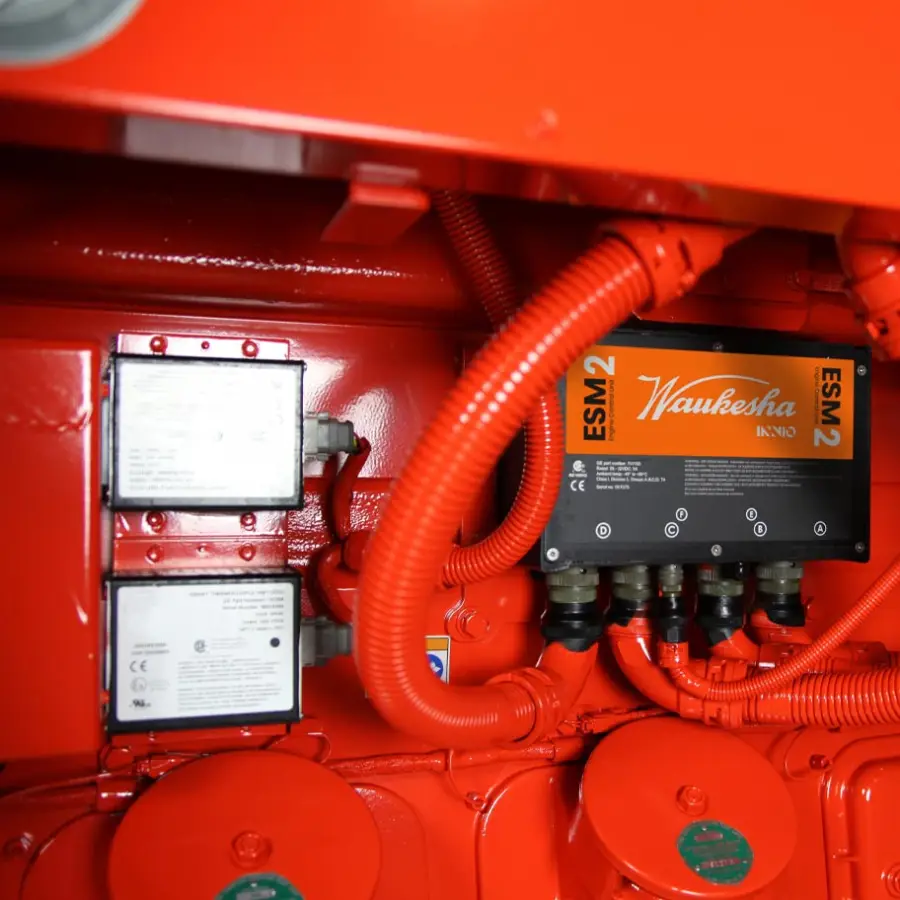

Almost any 12-cylinder VHP built after 1982 can be upgraded to a Series Five engine. This upgrade helps increase power and improve fuel consumption while reducing downtime, operating costs, and, most importantly, emissions. The major components of the Series Five engine include the camshaft, turbochargers, intercoolers, pistons, cylinder heads, and ESM2 controls system – all parts that are typically swapped during a major service interval, making an overhaul the optimal time for an upgrade.

The Waukesha VHP Series Five engine delivers 13% more power, 10% better efficiency, greater fuel flexibility resulting in:

39% more

power on propane

75% reduction

of THC emissions

20% lower

lifecycle costs

30% longer

service intervals

These improvements directly reduce the total cost of ownership for midstream operators.

One recent success story involves a midstream company operating in the Rockies region with 10 Waukesha VHP Series Five engines running in their fleet. The units were previously 7042 or 7044GSI driven packages purchased as used equipment and revamped with a mix of overhauls, upgrade kits, and engine swings. This operator also purchased six of Waukesha’s pre-production 7044GSI Series Five engines, the first non-field test engines sold, with the first unit commissioned in June 2018. They added two more production models and converted two units using a Series Five upgrade kit.

Due to the success and reliability of the initial units, seven more Series Four to Series Five upgrades are in process or scheduled, which will bring them to a total of 17 Series Five engines—offering one of the best low carbon option fleets contributing to responsibility producing natural gas. All but one unit is used for gas lift purposes with 80 psi suction and 1250 psi discharge pressures. All machines run reliably at >4680 foot elevation and on >1300 Btu fuel.