Midstream Storage

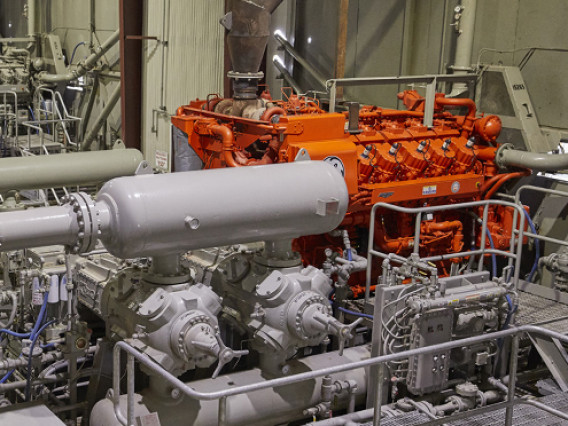

In colder climates, natural gas consumption fluctuates with the seasons, but natural gas production is a continuous, year-round process. Gas produced during times of low demand is bought more cheaply by gas companies and stored for later use when consumption levels-and prices-rise. Compressors, such as those driven by INNIO's Waukesha gas engines, are integral to the storage and retrieval process.

How it works?

During warm weather when demand is low, gas is stored in underground formations, such as depleted reservoirs or salt cavities. Gas engine-driven compressors force the gas into the storage cavities. Later, when demand rises with the onset of colder weather, compressors recover the gas from the storage site.

In areas where electricity is not readily available or is unreliable, a dependable engine driven compressor system is essential to keeping the storage and retrieval process operating.

Gas engine-driven compressors operating on the same gas they compress are a cost-effective alternative to compressors powered by electricity.

Engine-driven compressors can help to reduce overall energy costs by reducing electricity use during peak demand times.

A more efficient engine – one that compresses more gas while using less fuel – improves operational productivity and profitability.

INNIO's portfolio of Waukesha gas engines for compression applications offers multiple options to address individual operational needs and widely varying local emissions requirements.

Features & Benefits

- Durable: INNIO’s Waukesha gas engines perform with extreme reliability in remote and often harsh environments.

- Greater productivity: INNIO's Waukesha engines run at full power at higher altitudes and higher ambient temperatures, compressing more gas for more profit.

- Reduced costs: Gas engines can reduce operating costs significantly compared to electric motor-driven compressors by reducing peak demand charges.

- Emissions flexibility: INNIO offers technology options to meet most local air quality mandates.

- Lower emissions per horsepower: Rich-burn Waukesha gas engines with 3-way-catalyst enable more horsepower per site for more productivity and profit.

- Total engine control: INNIO's Waukesha ESM* fully integrated control and diagnostics system optimizes engine performance and maximizes uptime.