Built to Work

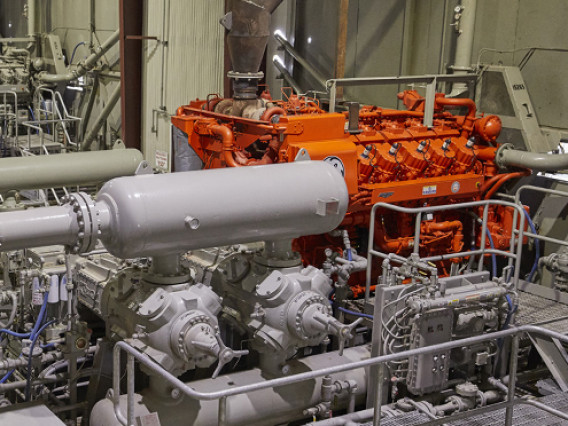

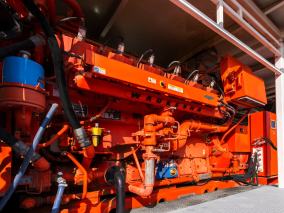

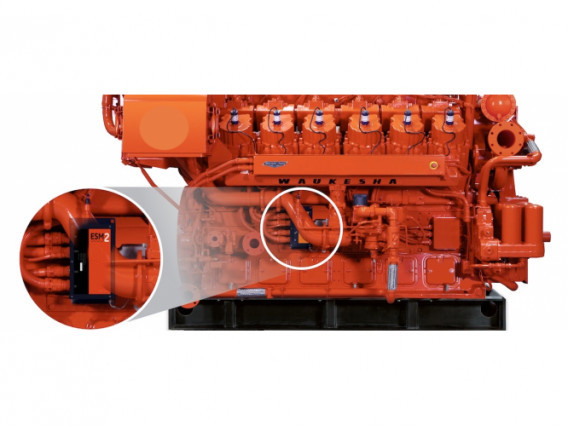

ESM2 with AFR2 Control Upgrade

- Availability

- Emissions

The next generation of controls for Waukesha* engines offers functionality, benefits, and a simplified user experience.

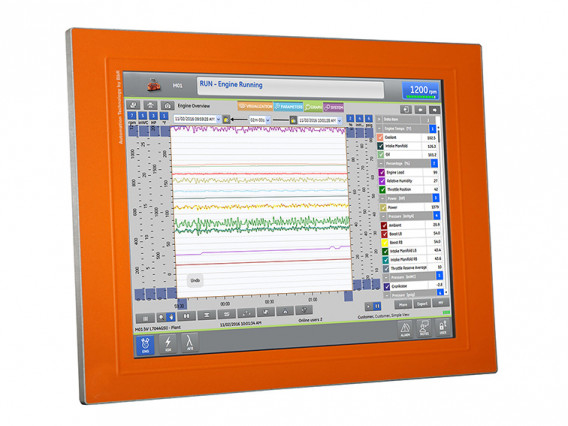

A large, full-color touch screen display panel allows users to see all engine parameters, trend data, view manuals and service bulletins, and walk through troubleshooting steps, eliminating the need for a laptop computer. Now with the ability to read exhaust and main bearing temperatures and oil pressure permissive for starting, your investment is protected more than ever!

What can this upgrade do for you?

Increased engine uptime and improved availability, through:

- Knock detection algorithm that adjusts timing to keep your engine running through changes in fuel quality and ambient conditions.

- Misfire detection utilizing sensors monitoring every cylinder combustion event to ensure optimal uptime and fast identification of combustion-related faults.

- Ignition power module with advanced diagnostics monitors spark plug performance and life to predict maintenance intervals and increase spark plug life.

- Remote monitoring connectivity capabilities to INNIO’s APM system to remotely monitor engine and driven equipment health, monitor and improve equipment reliability, and optimize plant performance.

- Ignition timing is based on a higher resolution map allowing for tighter control and reduced exhaust temperatures on hotter fuels.

Reduced maintenance cost through improved engine / controls serviceability and faster troubleshooting including:

- One ECU combines the use of multiple modules utilizing a smaller footprint on the engine, making servicing the engine easier.

- Industrial PC HMI provides all engine control inputs and diagnostic information onsite without the use of an additional computer or laptop.

- Support and fault diagnostics for nearly every engine system integrated into onsite HMI panel help to identify and resolve issues quickly with step-by-step troubleshooting guides, reducing engine downtime.

- Advanced power distribution box with power conditioning and fault monitoring that is communicated to the HMI panel reduces downtime and simplifies troubleshooting issues.

How we get you there?

ESM*2 control upgrade includes:

- Engine control unit (ECU) with knock sensors, ignition system, and governor actuator

- New upgraded harnesses, wireways, and engine sensors

- Human Machine Interface (HMI) industrial PC touch-screen control panel

- Power distribution box with fault logic communicated to ECU

- Customer interface harness

- Air/fuel ratio control (AFR2 functionality)

- Exhaust and main bearing thermocouples integrated with ECU

ESM2 offers a variety of control features, including:

- Start-stop control

- Engine safeties

- Fault logging and diagnostics

- Data trending and logging through HMI

- Service tool with online troubleshooting guide and engine manuals integrated into HMI

- Remote monitoring capabilities utilizing INNIO’s predix-enabled Asset Performance Management (APM) software

Find your version:

F3514GSI/F3524GSI |

Option I |

Option II |

Option III |

Option IV |

| ESM2 | ✔ | ✔ | ✔ | ✔ |

| Harnesses / Mounting Brackets | ✔ | ✔ | ✔ | ✔ |

| Power Distribution Box | ✔ | ✔ | ✔ | ✔ |

| AFR2 | ✔ | ✔ | ✔ | ✔ |

| Exhaust / Main Bearing Thermocouples | ✔ | ✔ | ✔ | ✔ |

| HMI Industrial PC | ✔ | ✔ | ✔ | ✔ |

| Gear Housing | ✔ | |||

| Flywheel & Housing | ✔ | |||

| Cam Timing Disc | ✔ | |||

| Gas Regulators | ✔ | |||

| emPact 0.15g NOx Catalyst System2 | ✔ | ✔ | ✔ | ✔ |

2 Optional

L5794GSI |

Option I |

Option II |

Option III |

Option IV |

Option V |

| ESM2 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Harnesses/Mounting Brackets | ✔ | ✔ | ✔ | ✔ | ✔ |

| Power Distribution Box | ✔ | ✔ | ✔ | ✔ | ✔ |

| AFR2 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Exhaust/Main Bearing Thermocouples | ✔ | ✔ | ✔ | ✔ | ✔ |

| HMI Industrial PC | ✔ | ✔ | ✔ | ✔ | ✔ |

| APM (remote monitoring capability) | ✔ | ✔ | ✔ | ✔ | ✔ |

| Flywheel & Housing | ✔ | ||||

| Gear Housing | ✔ | ||||

| Cam Timing Disc | ✔ | ||||

| Gas Regulators | ✔ | ✔ | |||

| emPact 0.15g NOx Catalyst System2 | ✔ | ✔ | ✔ | ✔ | ✔ |

2 Optional - Requires advanced breather

L7044GSI |

Option I |

Option II |

Option III |

Option IV |

Option V |

| ESM2 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Harnesses/Mounting Brackets | ✔ | ✔ | ✔ | ✔ | ✔ |

| Power Distribution Box | ✔ | ✔ | ✔ | ✔ | ✔ |

| AFR2 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Exhaust/Main Bearing Thermocouples | ✔ | ✔ | ✔ | ✔ | ✔ |

| HMI Industrial PC | ✔ | ✔ | ✔ | ✔ | ✔ |

| APM (remote monitoring capability) | ✔ | ✔ | ✔ | ✔ | ✔ |

| Flywheel & Housing | ✔ | ||||

| Gear Housing | ✔ | ||||

| Cam Timing Disc | ✔ | ||||

| Gas Regulators | ✔ | ✔ | |||

| emPact 0.15g NOx Catalyst System2 | ✔ | ✔ | ✔ | ✔ | ✔ |

2 Optional - Requires advanced breather

Other Services and Support

Built to Work

Tougher

with enhanced reliability, availability and efficiency.

Longer

with extended service intervals and comprehensive engine upgrades.

Smarter

with enhanced controls and performance improvements through data analytics.

At Waukesha, we’re working every day to design and build engines and programs that help power your tomorrow.

OUR LEGACY IS YOUR FUTURE

News

Be the

FIRST TO KNOW

Sign up for Waukesha's Customer Portal to receive ongoing insights, product innovations and more.

Start

A DIALOGUE

Send us a message and we’ll contact you to start the conversation.